When deciding on the appropriate cutting tool for a particular application, it is difficult to determine

whether a standard tool or a special tool is preferable. The ideal tool selection is contingent on various

factors, such as the nature of the business situation, the manufacturing program, the production type, and

sometimes personal preferences. Standard cutting tools, produced by a specific tool manufacturer, offer high

versatility and are appropriate for machining a diverse range of parts that come in different shapes.

Furthermore, the tool exhibits excellent performance capabilities when cutting various engineering

materials. To ensure seamless production processes, it is crucial to have the cutting tools delivered in a

timely manner. This is why standard tools are the foundation of tool stock management on metalworking

production floors.

A special cutting tool is designed for specific operations on a particular part, made of a specific

material, and used on a machine that requires a specific work holding fixture. This custom-engineered

tooling solution aims to provide the best possible performance and outcome. However, there is a downside to

this solution as it limits the tool's versatility, making it less adaptable to different applications. As a

result, special tools are primarily used for high-volume mass production, especially in the automotive

industry.

A special tool is not readily available and requires significant engineering effort, including concept

design, coordination with the customer, detailed design, and production. The delivery time for special tools

is significantly longer than that of standard tools. Metalworking shops often face a dilemma when choosing

between standard or special tools, which can impact project timelines. The question remains: which tool will

provide the best solution? Should shops rely on readily available standard tools or opt for a highly

efficient special tool with a longer delivery time? Naturally, economic factors such as cost per unit and

tool costs should be taken into consideration. All things being equal, in an ideal situation where

production programs, processes, and inventory are planned, the answer is clear. Therefore, the maximum short

lead time is an important factor when choosing a special tool.

Special tools vary in their design complexity. Some are simple modifications of standard tools, such as

changes to the corner radius or tool length. These modifications fall under the category of "semistandard"

products, which can be manufactured relatively quickly. The design complexity of a special tool is

determined by a pre-design study that assesses the customer's manufacturing limitations, accompanied by cost

calculations and production time. The results of the study determine the limits and cost-effectiveness that

correlate to the special tool's delivery time. However, there are additional ways to reduce the delivery

time of special tools, such as using solid tools with exchangeable heads, bodies of indexable cutters, or

replaceable inserts. The tool manufacturer's delivery times and production abilities play a significant role

in the final decision on how to proceed.

One alternative to engineered special tools is modular tooling, such as ISCAR's MULTI-MASTER (shown in

Fig.1), which features rotating tools with exchangeable solid carbide heads. This tooling system includes a

wide range of tool bodies (referred to as "shanks" in the family nomenclature), adapters, extensions, and

reducers that enable the configuration of the required tool for diverse machining operations.

Additive manufacturing (AM) presents new opportunities for special tool solutions. This technology allows

for the quick production of tools with complex profile designs. Although finish cutting and grinding

operations are still necessary, the fast manufacturing of pre-shaped products that are very close to a final

shape is fascinating (as shown in Fig. 2). Additionally, 3D printing can be used to fabricate carbide

inserts without the need for a die-set, which significantly reduces production time and costs. This process

is an excellent way to create insert prototypes during the development stages and produce low-batch special

inserts. AM of carbide inserts and heads is gaining momentum and is highly capable of ensuring fast delivery

of customized tools and their components.

Metalworking shops can quickly manufacture and customize a special tool if an appropriate off-the-shelf

product is not available. However, they may not have the means to complete the full cycle of toolmaking. In

such cases, tool manufacturers can provide semi-standard tools as standard items, which can be adapted by

the customer to their final shape. These semi-finished products can include blank bodies, blank inserts, and

blank heads. Some cutting tool manufacturers, such as ISCAR, offer this option and include blanks in their

standard product range.

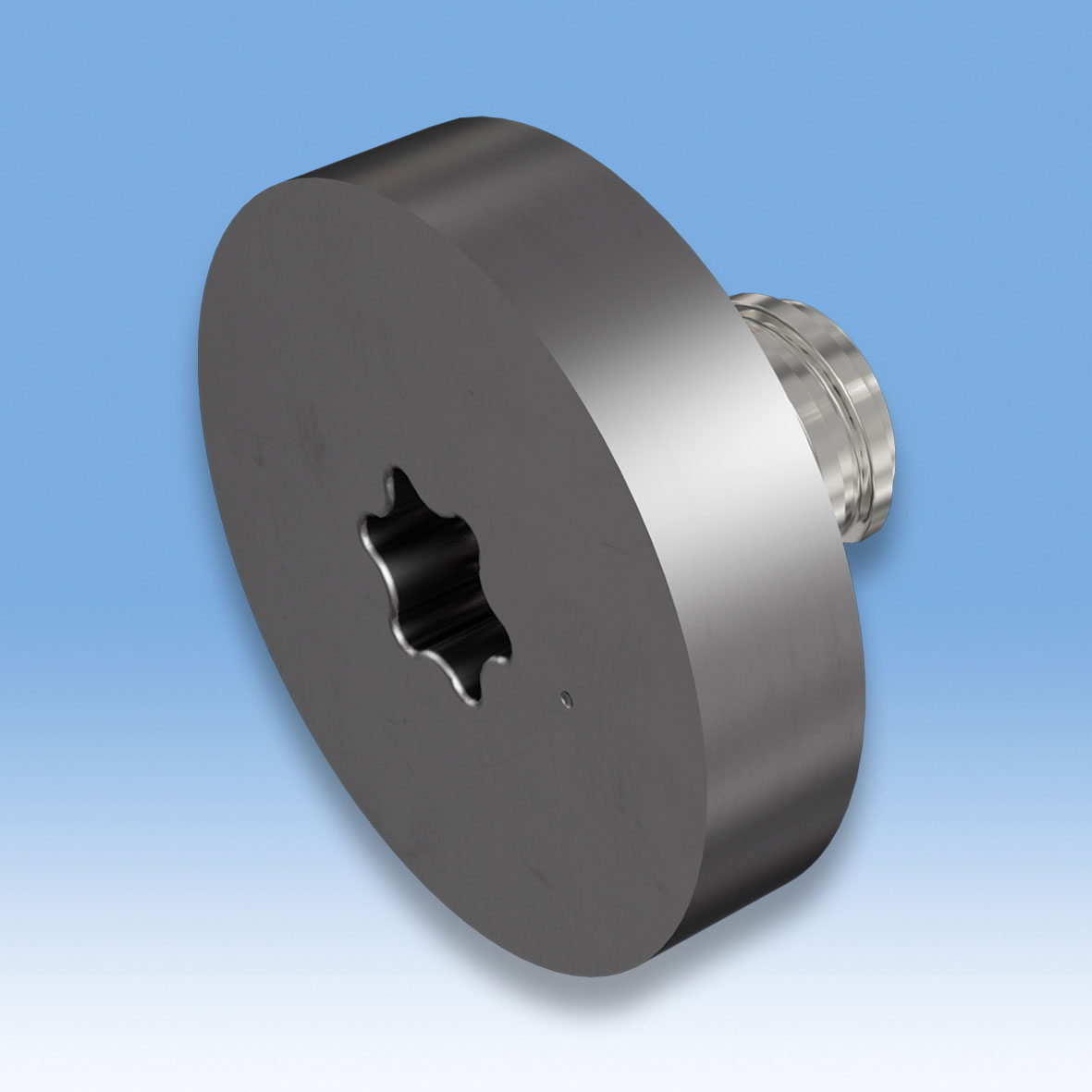

The MULTI-MASTER family offers extra-long shanks with an inner

MULTI-MASTER thread on the front face and a center hole on the back face, which can be cut and shaped by the

customer. Recently, ISCAR introduced uncoated carbide blank heads with two sections: a disc-form front area

with a hexalobular (TORX) recess on the face, and a rear area with an outer

MULTI-MASTER thread (Fig. 3). These heads are intended for producing special items to be mounted on

MULTI-MASTER shanks at the customer's machine shops for different machining operations such as milling

slots, grooves, threads, splines, gears, and more.

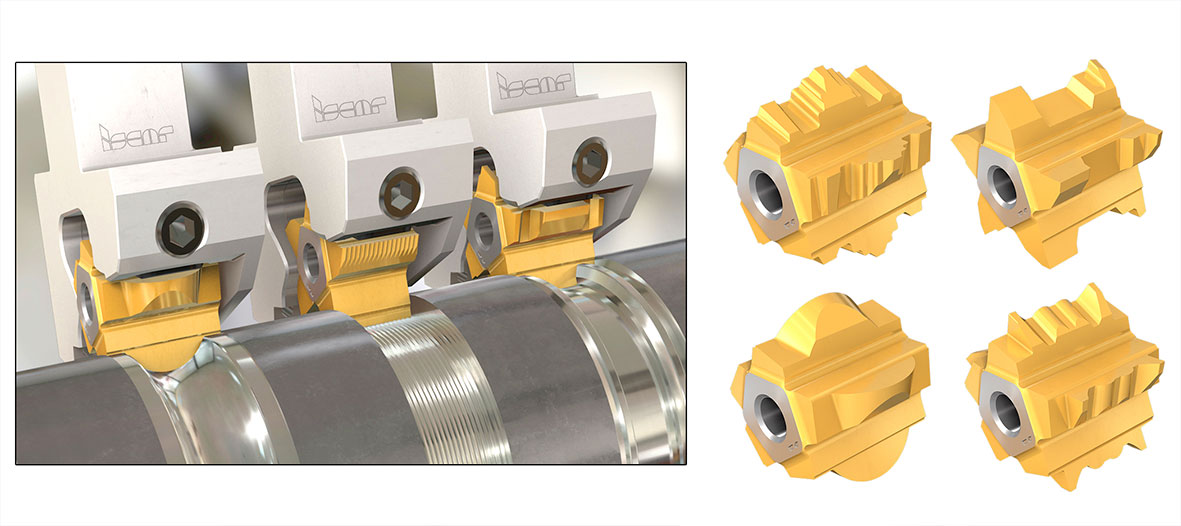

ISCAR has also added a group of unique PENTACUT-27 blank inserts with five edges for tailor-made profiles to

their product portfolio (Fig. 4). These starlike carbide blanks can be ground by the end-user to form

different shapes for shallow profiling and grooving depths when machining pulleys, bearings, and fittings.

Customers who produce special tools from blanks are limited compared to ordering specially tailored tools

from cutting tool manufacturers. However, when time is of the essence, customers can find the most

appropriate solution within given constraints by creating their own specially tailored tools. By providing

customers with the ability to create their own tools, new horizons are created to overcome the everyday

obstacles of manufacturing.